Product Description

Tender and Complete spring installation instructions

- Secure machine in Park. And then measure front ride height at forward, lower a arm mount, then record. Then measure rear ride height right below the tow hook, and record.

- Lube and clean threads on all shocks with wire brush and WD40 type lube.

- Lift the front of the machine and remove the shocks. Now with shock removed loosen the large top spanner nut utilizing the holes or grooves. Loosen nuts all the way to the reservoir. Remove lower coupler and remove springs. Add new tender springs. Tighten the spanner nut down to touch the tender spring and then tighten down 1 inch. This puts tension on the spring. Lower the machine off jack and settle the suspension by moving the machine. Measure ride height and then set ride height according to tire size as stated below. ** MOVING THE SPANNER DOWN WILL LIFT THE MACHINE, MOVING THE SPANNER UP WILL LOWER THE MACHINE

*******REMEMBER ALL MEASUREMENTS CAN VARY. THIS IS JUST A STARTING POINT. PLEASE ADVISE US AT 2563090200 IF YOU HAVE A MORE ACCURATE MEASUREMENT. ALL MEASUREMENTS ARE FROM STOCK MACHINES*****

- Re-install shocks (we will fine tune after we do the rear). FINE TUNING will be setting the ride height. We do this because all machines are loaded differently, from personal customizations.

- Rear – lift machine securely

- 1000xp, Turbo, and PRO XP models do not have to be taken off. Simply loosen the spanner nut and slide the lower collar off using the slot. Install tender springs. Tighten the spanner nut until it touches the top of the spring and then tighten 1 more inch. You will fine tune after the machine has been settled.

- 900s/1000s/General Remove rear shock and loosen spanner nut all the way. Slide springs up and utilize slots on the lower collar to remove the collar and remove the springs. Install smaller tenders and set spanners at 1 inch of pre-load. You will fine tune after the machine has been settled.

- Reinstall all shocks and torque bolts.

- Now that all hardware is torqued properly, tires are re-installed. Lower the machine off the jack and move the machine forward and backwards 3ft at a time for a few times to settle the suspension.

- FINE TUNE the preload with the ride height measurements supplied here. Adjust the spanner nut UP OR DOWN until ride height is achieved. Remember +/- .25 inches is ok.

- THE FINE TUNE usually formulates to the following , FRONT for every .5 INCHES OF PRELOAD EQUATES TO 1 INCH OF RIDE HEIGHT. REAR for every 1 INCH OF PRE LOAD EQUATES TO 1 INCH OF RIDE HEIGHT

- MOVING THE NUT UP WILL LOWER THE MACHINE, MOVING THE NUT DOWN WILL RAISE THE MACHINE

Tire to ride height measurements for High Lifter model machines add 2.5inches to the measurements listed below. They are designed to sit higher form Polaris.

If you have cross over rings set them 2 inches above the black slider after you have set your ride height and lowered your machine and settled the suspension.

28=13.5 +/-.5

- 29=14

- 30=14.5

- 31=15

- 32=15.5

- 33=16

- 34=16.5

- 35=17

- 36=17.5

For The PRO XP / TURBO R / Pro R

- 29=15

- 30=15 1/2

- 31=16

- 32=16 1/2

- 33=17

- 34=17.5

- 35=18

Rear will set a half inch lower at rest than the front measurements above. At point measured in step 1.

In some instances you may need to utilize a spring compressor. If a compressor is needed you can borrow them from your local parts store. For Walker Evans 4 Seat Models (NOT GENERAL XP) we have sent a shorter spring for the front to help make install easier and safer.

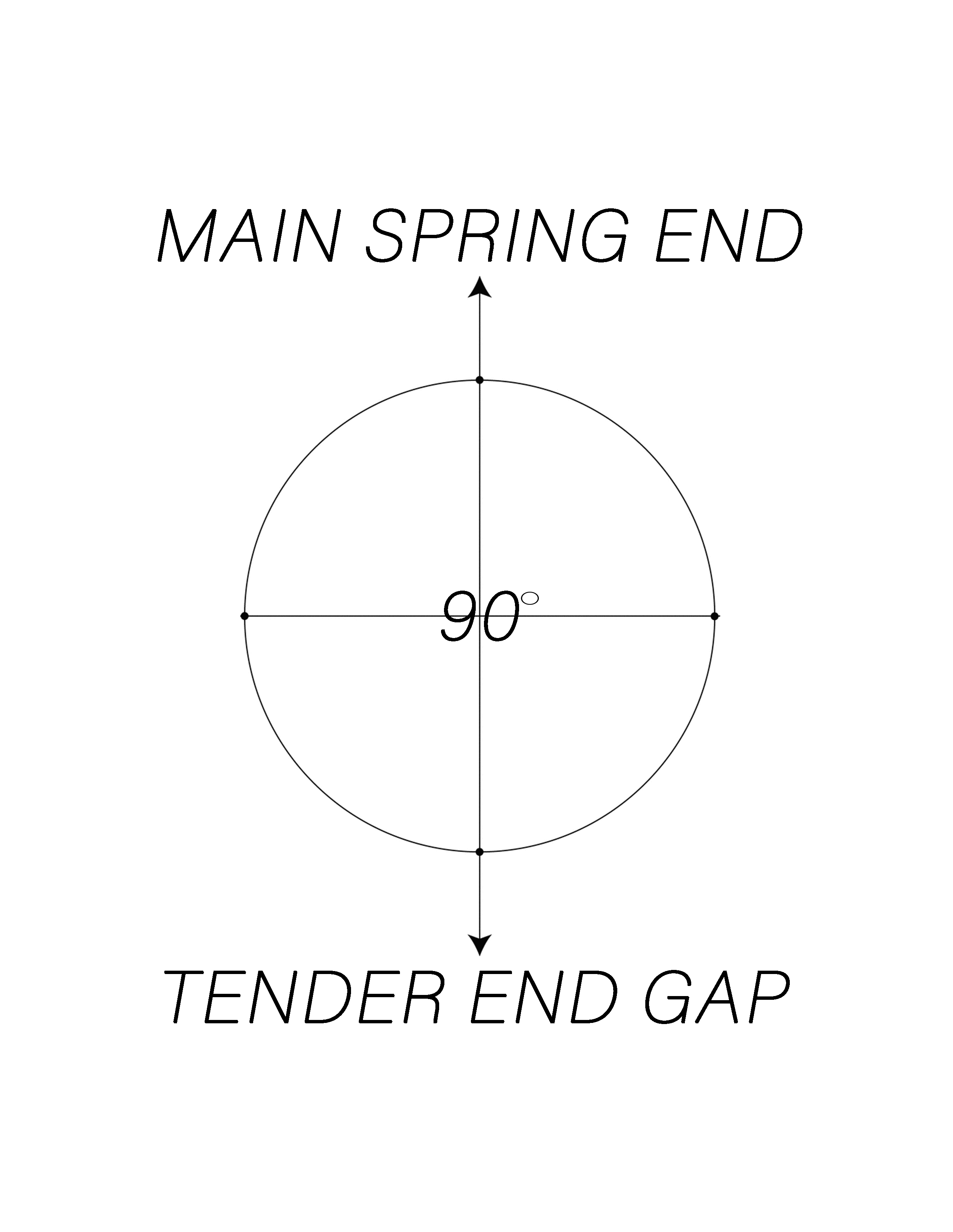

Springs are labeled with location to where they need to be placed.